Both the VB and VC series are based on the intelligent identification counts of the line-array CCD matching software algorithm. But the principle is different,and the applicable materials are different.

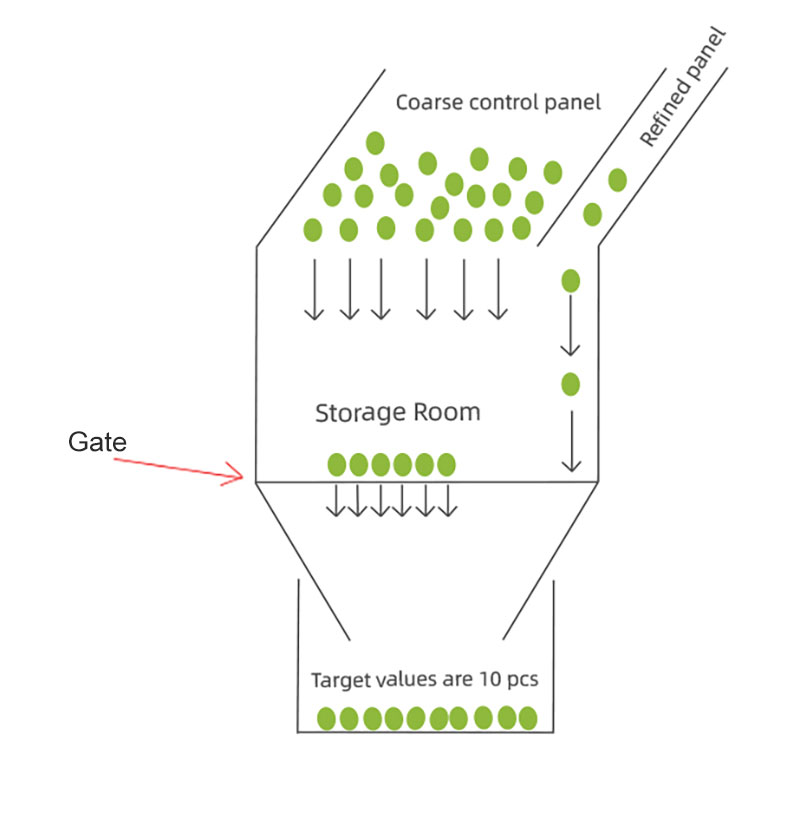

Falling material principle diagram of VB series counting packing machine

VB counting packing machine has two falling material mode

The

first type: the gate of the storage chamber is closed, and most

materials enter the storage chamber through the coarse control panel.

After reaching the set quantity, wait for the refined panel for

refilling until the total quantity reaches the set quantity requirement,

for example,the total number needs 100, it can be set to 95 pieces

falling through the coarse control panel, because the plate surface is

wider, it may fall 92 or 97, then the remaining number will fall through

the refined panel, and finally reach 100 pieces. The gate is opened,

and all materials fall into the packaging bag or other collecting device

together.

The second

type: the counting supply still adopts the mode of coarse control panel +

refined panel, but the gate of the storage chamber is open. During the

counting process, the materials will directly fall into the packaging

bag or other collection devices without passing through the storage

chamber to accumulate.

For some hooked materials, if all the materials fall together, they are

easy to stick and not easy to fall, forming a blockage in the storage

room. In addition, when the material with a larger shape and the

quantity is large, due to the limited space in the storage room, the

lower hopper is closed-end,so it is easy to block the material. So using the second mode,the materials fall apart and will not be blocked, which is a good solution to solve this problem.

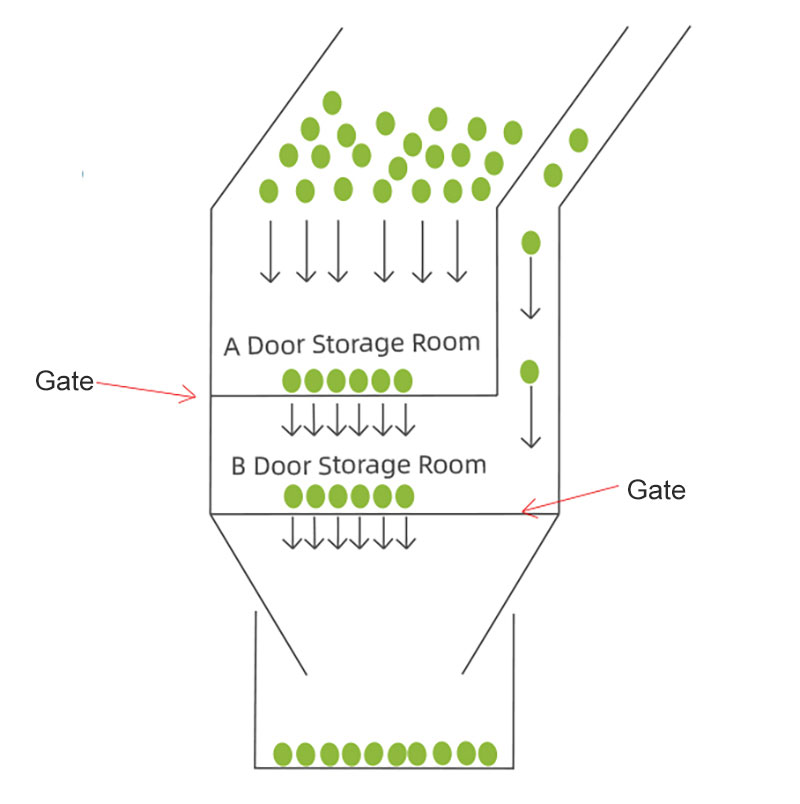

Falling material principle diagram of VC series counting packing machine

Most materials enter the storage room A through the coarse control panel. When the set quantity is reached, the gate A opens and drops to the storage room B, and waits for a small amount of replenishment from the refined panel. While the material is being refilled, A door is closed, and the counting of the next package of materials is continued. When the material in the storage room B is finished and the total demand is reached, the gate B is opened, and all the materials fall into the bag or other collecting device.

Although both VB and VC are used for accurate feeding through the coordination of coarse control panel + refined panel, the choices are different due to different falling material methods.

1.VC is not suitable for heavy and bulky materials, because the space of storage chambers A and B is limited, and space is required for the gate opening and closing.

Parameter comparison

|

Model |

||

|

Dimension |

1180*600*970mm |

1220*650*1250mm |

|

Accuracy |

99.99%,no negative deviation |

99.99%,no negative deviation |

|

Material Dimension |

Ø3-30mm |

Ø3-30mm |

|

Production Efficiency |

Ø10mm,1000pcs/bag,3bag/min |

Ø10mm,1000pcs/bag,6bag/min |

|

Power Supply |

0.75KW |

1.0KW |

|

Weight |

180KG |

220KG |

|

Power Consumption |

AC220V,50HZ |

AC220V,50HZ |

|

Bleed Pressure |

0.6-0.8MPa |

0.6-0.8MPa |

In here you can find many different type of intelligent counting packaging machines.

Pick up: hardware counting packing machine,seed counting packing machine,food counting packaging machine,tablet counting and filling machine.

If you have any question, please contact us.

Интернет Сервис